Correx: cheap, light, useful. Choose any three

Synopsis : From quick fixes to permanent solutions, Correx – extruded, twinwall, fluted polypropylene – has multiple uses in beekeeping. If you learn how to fold, stick and shape it you can save time, money and space. Here are just a few of the things I use it for.

Introduction

The Spring honey is almost ready to harvest. Supers went from ”filling nicely” to ”Woah! Damn that’s heavy” in the space of a week. They’re now fast approaching ”No more than two at a time” territory which means; a) they’re full, and/or b) I’m less strong than I used to be {{1}}.

The corpulent supers prompted me to rummage through a teetering stack of equipment to try and find sufficient clearer boards to use before removing the honey supers for extracting.

Clearer boards are effectively one-way ‘valves’ that funnel the bees down into the brood box {{2}}.

These are two and bit times a season pieces of kit … the Spring and Summer honey harvests and irregular usage to empty the odd brood box when compressing colonies prior to the winter. The rest of the time they sit, unused, unwanted and – not infrequently – in the way.

And, for convenience, you need more than one.

I like to have one for every hive in the apiary, particularly when taking the summer honey off. That way you can strip all the hives simultaneously, so avoiding problems with robbing. None of my apiaries are particularly big, but it still means I’ve needed up to a dozen clearer boards at a time.

That’s a lot of wood and limited-use kit to sit around unused. I therefore build lots of them from Correx.

This post isn’t about clearer boards. I’ve described those before.

Instead it’s about Correx and the myriad of uses that it can be put to.

If you don’t use it you’re probably missing out.

If you do, you probably have some additional uses to add to the list below.

Correx

Correx is a registered trademark owned by DS Smith. Other trademarks (by other companies) include Cartonplast, Polyflute, Coroplast, FlutePlast, IntePro, Proplex, Twinplast, Corriflute or Corflute … and there are probably some I’ve missed.

It’s all very similar stuff, variously described as corrugated plastic or corriboard, and perhaps more accurately described as an extruded, twinwall, fluted polypropylene.

If you don’t know what I’m talking about then you’re probably familiar with the material they make For Sale signs from … that’s Correx {{3}}.

Correx is lightweight, impervious to most oils, solvents and water, relatively UV resistant and recyclable. These characteristics make Correx ideal for a range of beekeeping applications.

It is easy to cut and can be folded, with or across the ‘grain’ if you know the tricks of the trade.

Correx is available in a range of thicknesses – typically 1-8 mm. Two millimetre Correx is often used as a protective floor covering in new buildings. However, it’s rather thin and flimsy.

Almost everything I use is 4 mm and so, unless I state otherwise, assume that’s what I’m referring to in the text below.

Almost certainly the stuff I use is not Correx, but I’ll call it Correx for convenience {{4}}.

Before discussing {{5}} applications I’ll make a few comments on sourcing Correx and cutting, gluing and folding it.

Free Correx

For Sale signs belong to the estate agent selling the house. However, they’re often not collected after the house sale completes and are dumped in a nearby ditch, stuffed down the side of the garage or otherwise discarded. Many still have the 2.4 m wooden post attached.

If they really are unwanted it’s often a case of ’ask and ye shall receive’ … and, if the sign is in a ditch, you don’t probably even need to ask.

When I lived in a semi-urban area I used to carry a handsaw in the car to help my repurposing of these sorts of signs.

Elections are another good source, particularly if the candidate in your ward a) loses ignominiously, and b) immediately retires. It’s unlikely the political party will find another Archibald Tristan Cholmondeley-Warner to stand for them, so the electioneering signs are – like the politician – surplus to requirements.

As always, never walk past a part-filled skip without having a good look at the contents 😉

Never!

Buying Correx

Correx is relatively inexpensive when bought in multiples of 2.4 x 1.2 metre sheets {{6}}. I’ve paid about £10 a sheet delivered for 5 or more, purchased from eBay, but can’t find anything quite that price when I had a quick look this week.

You might not think you need 14 square metres of Correx but you’d be surprised at the things it can be used for. It’s also easy to store behind a bookcase or in the shed.

It’s also worth asking at local plastics and printing companies that may have offcuts or failed print runs. It doesn’t matter what’s printed on the Correx {{7}}. There’s a beekeeper in Northern Ireland that crafted a nuc box out of election propaganda bearing a photo of the candidate. The nuc entrance was arranged to be the politicians mouth.

Be creative.

Finally, Correx is often used to make guinea pig cages or runs, so befriend a cavie-keeper and you might locate the mother lode {{8}} 😉

Correx engineering

Thin Correx (4 mm) is easy to work with. It can be cut with a Stanley knife. All you need is a good straightedge, a steady hand {{9}} and a sharp blade. Marking up the sheets is easiest in pencil as many pens don’t work on the smooth impervious surface {{10}}. Pencil works equally well on black or white sheets.

I’d recommend you don’t use scissors as they tend to crush the sheet. It’s also difficult to cut large sheets with a small pair of scissors.

Folding Correx

Correx has a ‘grain’ created by the vertical internal ribs that connect the upper and lower faces of the sheet. If you need to fold the sheet you’re working with, the method used depends whether you are folding across or with the grain.

To fold across the grain you need to crush the ribs without cutting through the upper face of the sheet. To achieve this use a pizza cutter and a straightedge. A pizza cutter is usually sufficiently blunt that the sheet isn’t cut. The crushed side of the sheet becomes the inner angle of the fold.

Making folded corners requires a little ingenuity but is obvious once you realise how the sheet folds {{11}}.

To fold with the grain requires a small amount of surgery. First cut on either side of a rib, then fold the sides back leaving a T-shaped piece – formed by the rib and a small piece of the upper face of the sheet – protruding. Then, with a steady hand and a sharp knife, cut the leg of the T away.

The sheet then folds easily with the uncut face forming the outer angle of the corner.

Gluing Correx

This is tricky. I’ve tried every glue in my workshop and none of them work. The surface of Correx has some sort of treatment that means that glues do not adhere. There are tricks that involve flaming the surface to remove the treatment, but – at least in my experience – they are hit and miss.

Usually miss 🙁

There are commercial hotmelt adhesives {{12}} that can be used – like the ones the estate agents use to stick two signs back-to-back – but they are quite expensive.

Whatever the surface treatment is, it also prevents many sticky tapes adhering properly or permanently.

But there’s one exception … Unibond Power Tape Plus. It’s available in silver and black. Critically for beekeeping it’s both waterproof and temperature resistant. This tape is about a fiver a roll and this represents excellent value for money.

I’ve got some Correx hive roofs held together with Unibond Power Tape that have been in constant use since 2014, outdoors (obviously) in temperatures ranging from sub-zero to 30°C or more {{13}}.

Highly recommended.

To help the tape stick even better it’s worth gently abrading the surfaces to be taped together using wet and dry sandpaper and then cleaning with a solvent like acetone. Press the tape down firmly and check it in about a decade or so.

Uses

I’m going to concentrate on the uses I make of Correx, because those are the things I have experience of.

There are lots of other things you could use it for … for example, I’ve not built nuc boxes from Correx, but I know you can. They are increasingly used by the bulk commercial nuc suppliers. If you don’t want to build your own you can purchase these boxes for £9 to £12 each {{14}}, flat-packed, in National or Langstroth formats. These boxes tend to use interlocking tabs to hold them together, rather than tape or glue. They might be suitable for short term, summer usage, but not for overwintering a nuc colony.

Roofs

I’ve made lots of Correx roofs and they are still in everyday use, either on hives or on stacks of spare boxes. I’ve described how to build them in detail, together with their pros and cons.

Everything I wrote 7 years ago is still valid, so I won’t repeat it here.

A single 2.4 x 1.2 sheet of Correx is big enough to produce 8 roofs. Even if you can’t find Correx cheaper than £13 a sheet that’s still less than £1.75 a roof including the cost of the tape holding it together {{15}}.

I routinely successfully overwinter colonies with Correx roofs covering a 50 mm thick block of Kingspan insulation.

Semi-permanent division boards e.g for vertical splits

In my experience these are one of the few things {{16}} that cannot be satisfactorily made from 4 mm Correx.

These types of boards might be separating brood boxes for a month or more while one half of a vertical split requeens. During this time the board tends to warp. The bee space increases on one side and is destroyed on the other. Consequently the bees build unwanted brace comb above and below the frames.

I now only use my 4 mm Correx split boards in extremis. I know that some of the commercial beekeepers use 6 mm or 8 mm Correx split boards. The additional rigidity of the thicker Correx presumably withstands warping sufficiently.

If When I run out of equipment I’ve been known to use split boards as crownboards. For the same reasons – warping – I try and avoid using horizontal sheets of Correx in the hive for extended periods.

Temporary division boards e.g. Cloake and clearer boards

In contrast, Correx is ideal when used for limited periods in the hive. One obvious application is the removable slide in a Cloake board for queen rearing.

Mine was built from a For Sale sign rescued from a skip in Newcastle. It’s one of the thicker pieces of Correx I’ve used (6 or 8 mm) and is significantly more rigid than the standard 4 mm sheets. However, I’m sure that 4 mm would do as the slide is only in place for about 24 hours to induce the emergency response and initiate queen cell production.

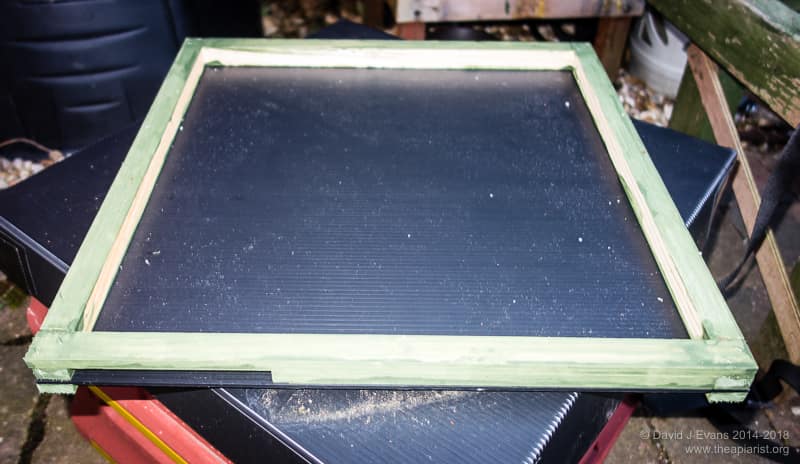

As I wrote in the introduction, the majority of my clearer boards are built from Correx. I now zip tie the escapes to the underside of the board {{17}} and then pair them with a simple eke when I need to use them for clearing supers.

These work fast and efficiently, they don’t warp and they can be separated from the eke and stored separately (where they take up little space) if/when the eke is being used for something else (like a spacer to provide an upper entrance, or whilst vaporising from above the brood box).

Floors

The only floors I’ve built with Correx are those for bait hives when paired with two stacked supers. These work really well.

Bait hives should have solid floors, so if I want to use an open mesh floor on a bait hive I simply lay a small sheet of Correx on the mesh and remove it once the hive is occupied.

Varroa trays

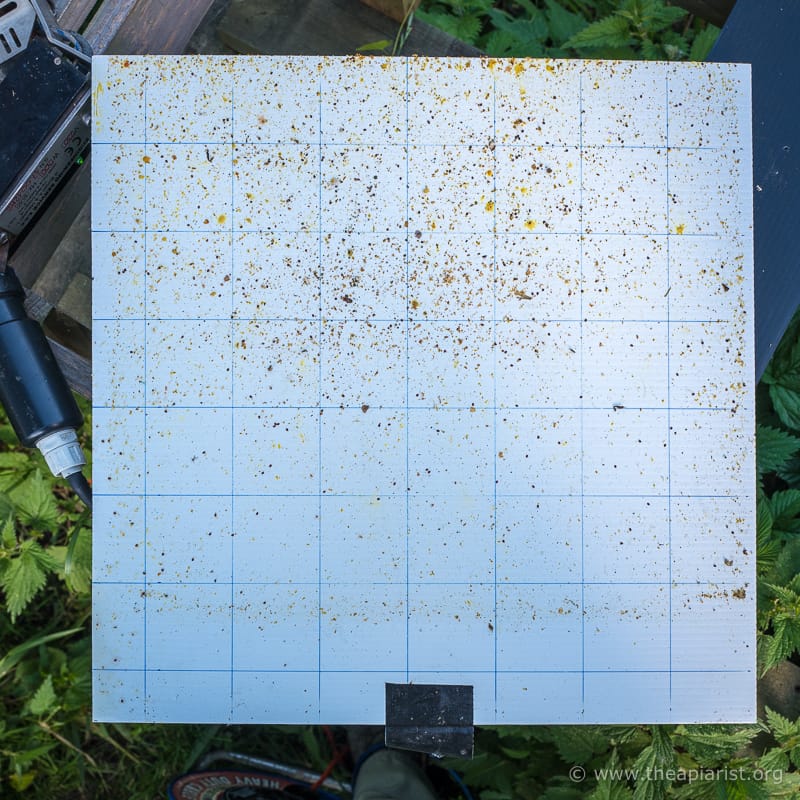

Most, or at least many, commercial Varroa trays are made of Correx {{18}}. To make counting mites easier it helps to draw a grid on the tray.

Of course, to make counting mites really easy it helps if there are few of them. Use miticides properly and at the right time. In that way your Varroa levels will never get too high and you’ll never run out of fingers when counting the mite drop 😉

OK, perhaps a slight exaggeration, but it’s certainly easier to count low numbers of mites rather than thousands. I’ve seen post-treatment mite drops so heavy you could trace patterns through the mite corpses with your finger, and the easiest way to count them was with a digital lab balance.

Ewww!

Landing boards

Almost all of my hives have Correx landing boards. Some are integral to the kewl floors I use …

… while others are attached to the outside of my bee shed.

You can paint Correx with a variety of different types of paint. Radiator enamel or car spray paint works well. Using different colours and/or decorating the landing board with distinctive shapes helps bees orientate to the hive entrance and reduces drifting.

For vertical surfaces, try sprinkling sand onto the semi-dry paint before over-spraying to provide laden foragers better grip when entering the hive.

My white Correx landing boards are starting to exhibit UV damage after 4-5 years of use. Either avoid white, paint them or put up with having to infrequently (and inexpensively) replace them.

Miscellaneous

Most of my nucs are red {{19}} or blue. When I’m making up lots of nucs for queen mating I pin Correx shapes above the entrance to help the bees – and particularly the queens – distinguish between the hives. Again this reduces problems with drifting.

Almost all my nuc boxes are Thorne’s Everynucs. These are well designed except for the cavernous entrance. Again, Correx can be used to fix the situation; I use it to block the entrance entirely for travel, or to provide a much reduced entrance that is easier for the small colony to defend.

I’m currently busy rearing my first queens of the season. The method I’m using involves sealing the standard hive entrance and redirecting the bees to an upper entrance {{20}}. This process is really speeded up by leaning a sheet of Correx against the front of the hive, directing the returning foragers to the upper entrance.

Doing this stops the bees milling around the original entrance and is particularly helpful in borderline weather conditions e.g. low temperatures and intermittent showers {{21}}, when it prevents bees getting chilled.

Fat dummies for queen rearing? Correx to the rescue.

I could go on … but I won’t.

You’ve got the general idea by now.

If you’ve found additional uses for Correx then please add a comment below.

{{1}}: Probably both.

{{2}}: All mine are of a single design – blatantly copied from Polyhive on the BeekeepingForum.

{{3}}: At least in the UK … I’ve no idea what estate agents realtors use in the US.

{{4}}: It’s the best known trademark, the easiest to say and saves me typing the 34 additional characters needed for extruded, twinwall, fluted polypropylene.

{{5}}: Or at least presenting, I don’t want to get close to the 3000 words exceeded by the last three posts.

{{6}}: It’s should be delivered rolled or unfolded.

{{7}}: Like Vote Cholmondeley-Warner.

{{8}}: Or perhaps share the costs … and potentially even broaden your diet.

{{9}}: Or spare fingers.

{{10}}: Posca queen marking pens do though for inveterate ’notes on the roof’ beekeepers.

{{11}}: See here for more details.

{{12}}: Tecbond 261 for example.

{{13}}: And, since 2015, in the notoriously arid Scottish environment.

{{14}}: I’m not going to recommend any particular suppliers as I’ve no experience of any of them.

{{15}}: For comparison, and serving the same purpose, a flat-pack National hive roof in cedar is about £55.

{{16}}: For beekeeping that is … but you can build lots of other things, like boats and planes from Correx.

{{17}}: Standard duck or gaffer tape does not work – the escapes fall off within 24 hours in the warm, humid atmosphere. Unibond Power Tape does work, but zip ties are easier to remove.

{{18}}: As an aside, polystyrene Varroa trays discolour very quickly and this makes counting mite drop a frustrating exercise.

{{19}}: Which of course appears black to the bees

{{20}}: On which, more in a later post.

{{21}}: Typical queen rearing conditions here in Scotland.

Join the discussion ...